There is a first time for everything

Travelling summer intern Jean Sissener on board combination carrier

Just ask our travelling summer intern Jean Sissener. Jean spent his summer on board Combination Carrier MV Bangor, which trades with several ports in the US and Brazil. He was to be part of the crew who did the first ever simultaneous load and discharge in Brazil for a CABU vessel, and specifically highlighted this as a memorable experience when he returned to shore.

Being a fourth-year student in Marine Technology at the Norwegian University of Science and Technology (NTNU) in Trondheim, Sissener was excited for a different kind of summer internship compared to many of his classmates. Eight weeks on board MV Bangor. We asked him to share his experience and he accepted the challenge and took to the pen.

Preparing for life on board

My adventure started at the Head office in Oslo, where I got an introduction to the various business areas and an overview of what to expect onboard. One of the Ship Managers gave me a rundown of what to expect by going through the structure of the summer intern program. It was designed to give me both a functional understanding of the most important systems and components onboard as well as practical experience.

First ever simultaneous load and discharge in Brazil

I signed on the vessel in Burnside, Louisiana, where she was discharging bauxite. I was introduced to the captain and the crew and the procedures onboard and joined the crew in their daily work onboard. We stayed in Burnside for a week before we sailed down the Mississippi river and out in the Gulf of Mexico with direction for Houston, Texas. Some days were spent on anchorage outside Houston before we were alongside in the chemical terminal Vopak. After some days of loading Caustic soda, we were ready to head for the Brazilian port Alumar near the city of São Luís.

Cargo hold cleaning

We sailed across the Gulf of Mexico, to the Caribbean Sea before we were out in the Atlantic Ocean. The voyage from Houston to Alumar was 14 days and included a lot of preparations since the vessel was to load alumina and discharge caustic soda simultaneously. This was the first time for a CABU vessel to do simultaneous load and discharge in Brazil and I was very excited to be a part of it. We were only in Alumar for two days but I got the opportunity to go ashore in Brazil and see the beach and the city. After the operations in Brazil, another 14 days were spent on the way back to the US and up the Mississippi river. In the river we bunkered fuel for two days before we arrived in the port of Convent where I signed off.

What it’s like to be part of the crew

During my eight weeks on board I have had a very steep learning curve. I got familiar with the points in the checklist with the crew through their daily, weekly and monthly routines. They were helpful when I found it difficult to understand the function of a component or system and were happy to answer any of my questions or show me drawings and manuals to clarify. In addition to introducing me to the work routines on the bridge, deck and engine room, the checklist I had made it possible to explore the rest of the ship during inspections and other jobs. For a student in marine technology it was very exciting to see all the details onboard and get an understanding of how everything is connected.

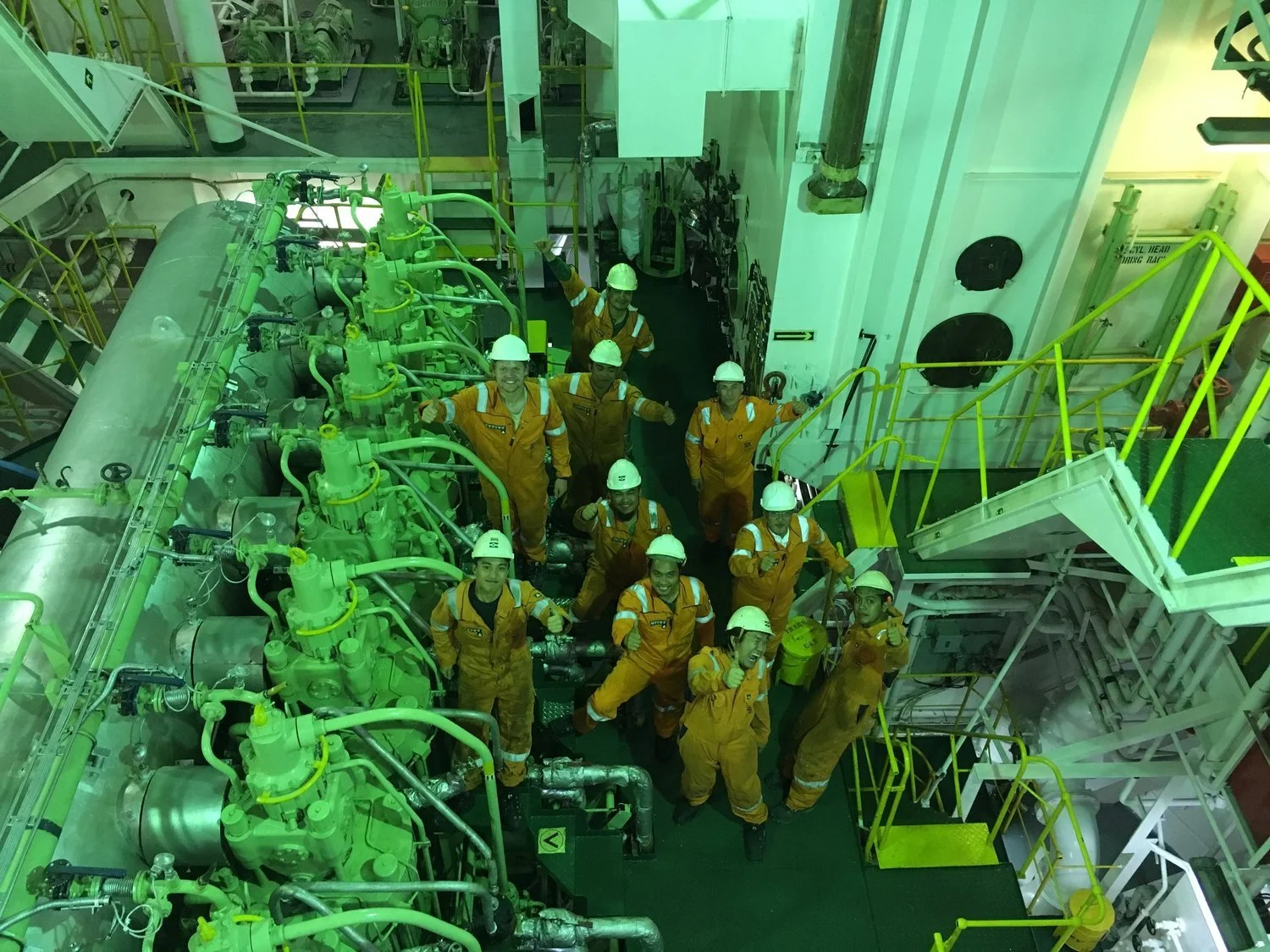

Jean with the MV Bangor crew

Since the vessel is a combination carrier it can load several types of cargo. I got to observe load and discharge operations of three different types of cargo in five operations. Before these operations could be completed, there had to be done a lot of preparations which I got to participate. Cleaning the huge cargo holds and making a loading or discharge plan that ensured sufficient strength and stability under the operations, are examples of these preparations.

Safety first

In addition to the technical and operational knowledge I have also learned a lot about safety management onboard and how international maritime regulations are followed regarding safety and environment. Each Saturday I was assigned to do the weekly safety routines together with an officer from the engine room. These routines included testing of bilge water alarms, fire alarms, the emergency generator, batteries and the two lifeboats. I also got to participate in weekly emergency drills including fire drills, lifeboat drills and bunker drills. The anti-pollution work onboard is very important and I learned how pollution is prevented and how the crew should act if there occur a pollution situation onboard. In addition to the regulations about oil pollution I learned how garbage and sewage should be handled according to the regulations.

Finally, I want to thank the crew and staff who made this experience possible for me. I have learned a lot and gained an experience that will be very useful in my future career in the Maritime Industry. If you’re thinking of doing something similar, I can recommend it!

Thank you!